In the field of stainless steel wire production, Tianjin Jingzhou Metal Products Co., Ltd. has become a leader in the industry with its excellent professional technology and strict quality control system.

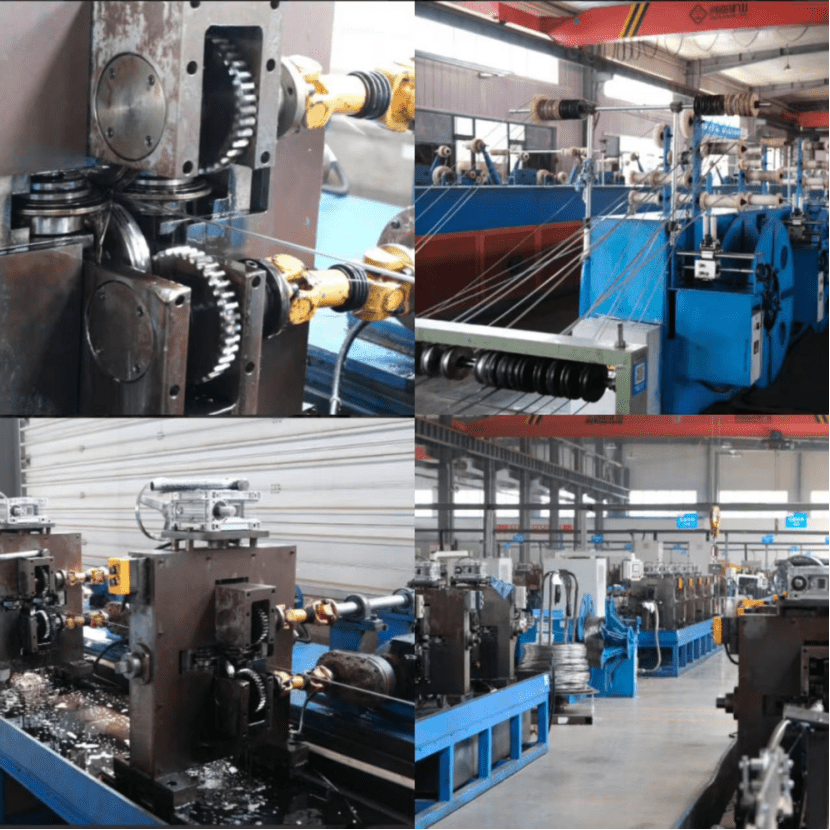

In terms of professional technology, the company has a high-quality and experienced R&D team. They continue to study and innovate, and have mastered the advanced stainless steel wire production process. Starting from the selection of raw materials, we carefully select high-quality stainless steel materials to ensure the basic quality of products.In the production process, precision wire drawing technology is used to make the stainless steel wire have a uniform diameter, smooth surface and excellent mechanical properties. At the same time, through the unique heat treatment process, the strength and toughness of stainless steel wire are improved to meet the needs of different customers.

Strict quality control system is a strong guarantee for our persistent pursuit of quality. The company has established a sound quality management system, from raw material procurement, production and processing to finished product inspection, every link is strictly controlled. We are equipped with advanced testing equipment, such as metallographic analyzers, hardness testers, tensile testing machines, etc., to conduct comprehensive testing on the chemical composition and physical properties of stainless steel wires. Each batch of products must go through multiple testing processes to ensure that they meet national standards and customer requirements. Only products that have passed strict testing can be sold out of the factory, providing customers with assured and reliable stainless steel wire.