In order to continuously improve the quality of stainless steel wire products, Tianjin Jingzhou Metal Products Co., Ltd. has recently taken a series of specific and effective measures.

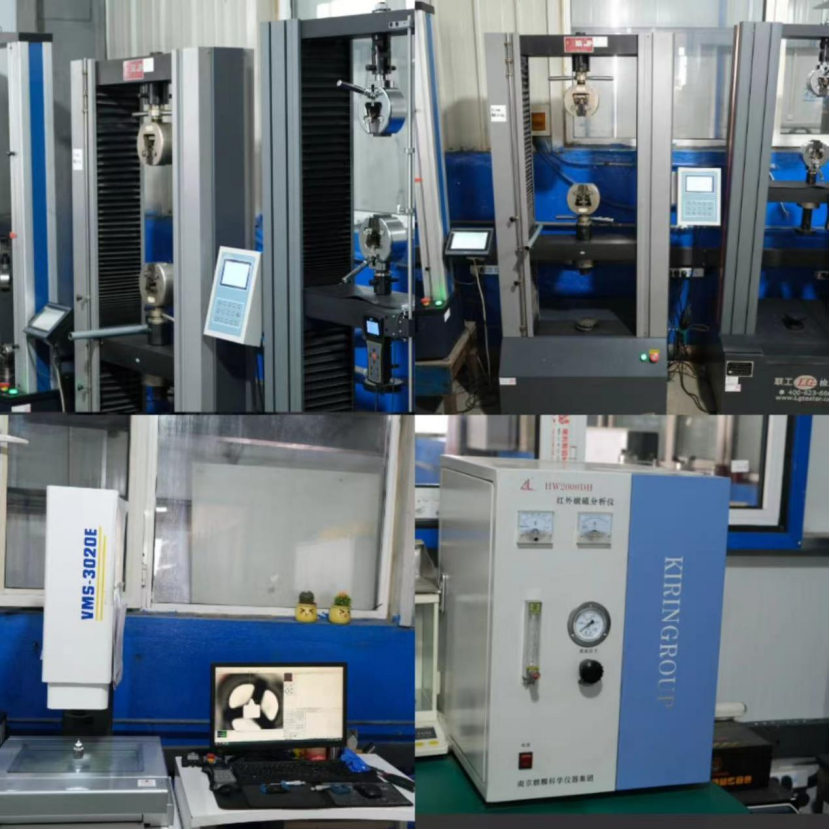

First of all, in terms of hardware equipment, the company has invested a lot of money to introduce advanced testing equipment. For example, the new high-precision electron microscope can clearly observe the microstructure of stainless steel wires and detect potential quality problems in time. There is also an advanced spectrum analyzer, which can accurately detect the chemical composition of stainless steel wire and ensure the purity and stability of raw materials. The introduction of these advanced equipment has greatly improved our ability and accuracy to detect product quality.

In addition, the company has optimized its production processes. Through a comprehensive combing and analysis of the production process, some unnecessary links have been removed and the production efficiency has been improved. At the same time, the monitoring of key links in the production process has been strengthened to ensure the stability of product quality. For example, in the drawing process, we have added real-time monitoring of the drawing speed and temperature to ensure the uniform diameter and surface quality of the stainless steel wire.